FACILITIES

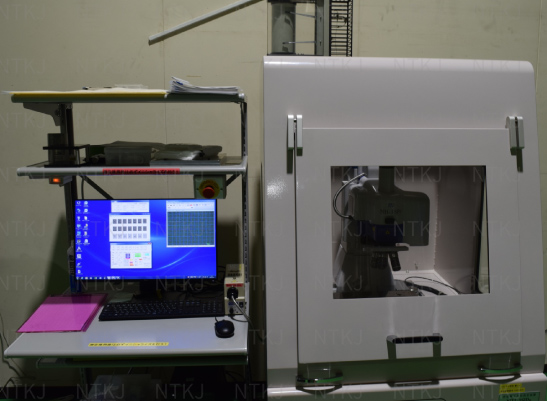

Measurement Equipment

Zygo NewView

Machine name

Zygo NewView

Specifications

Material

Various surfaces: opaque, transparent, coated, uncoated, specular, and nonspecular

Maximum Size

(H x W x D) 3.5 x 8 x 8 in. (89 x 203 x 203 mm);

larger sample sizes possible

Reflectivity

1-100%

Roughness

≤ 150 µm Rp standard; Slope dependent

Used for

Measurement via non-contact, three-dimensional, scanning white light and optical phase-shifting interferometry

Mitaka Koki NH-3SPs

Machine name

NH-3SPs “Ultra-precision point autofocus probe 3D measuring instrument”

Specifications

measuring range (X, Y, Z) =

150 x 150 x 15mm(NTKJ’s exclusive edition)

Z = 120mm (NTKJ’s exclusive edition)

scale resolution (X, Y, Z) =

0.01 x 0.01 x 0.001um

Used for

Fresnel lens mold, grating,

surface of aspherical lens mold

More info about

Mitaka Koki NH-3SPs here here

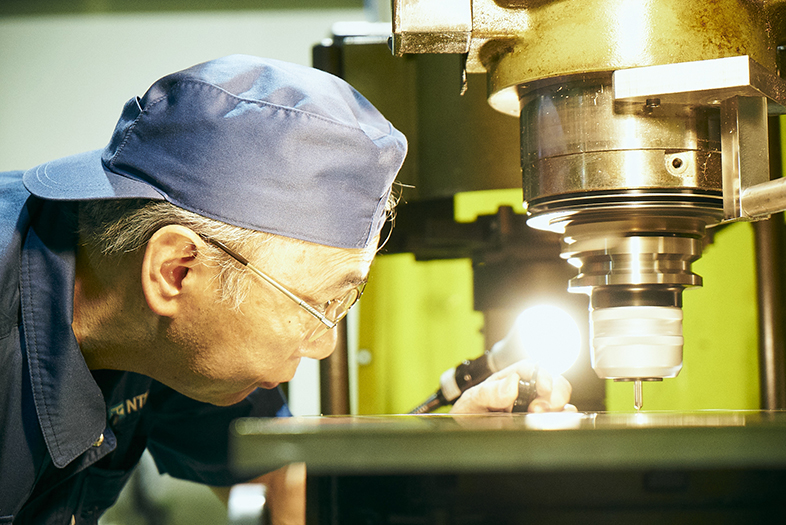

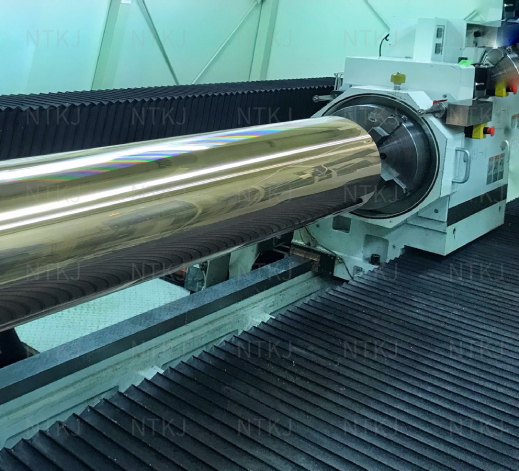

Ultra-Precision Machines

Machine name

Toshiba Machines ULR-635 (NTKJ Exclusive Design)

Specifications

Maximum machining wih: 2800mm

Programming resolution:

0.01um (X and Z axis), 0.0001 deg (B and C axis)

Used for

High-precision horizontal turning lathe used for precise grooving on the roll for optical sheetmolding.

More info about Toshiba Machines ULR here

Toshiba Machines UTD-2200

Machine name

Toshiba Machines UTD-2200 High Precision

Turning Machine

Specifications

Maximum workpiece diameter: 2200mm

Programming resolution:

0.01 um (X, Z axis), 0.00001 degree (B axis)

Used for

Fresnel lens manufacturing

More info about Precitech

Shibaura Machine UTD-2200 here

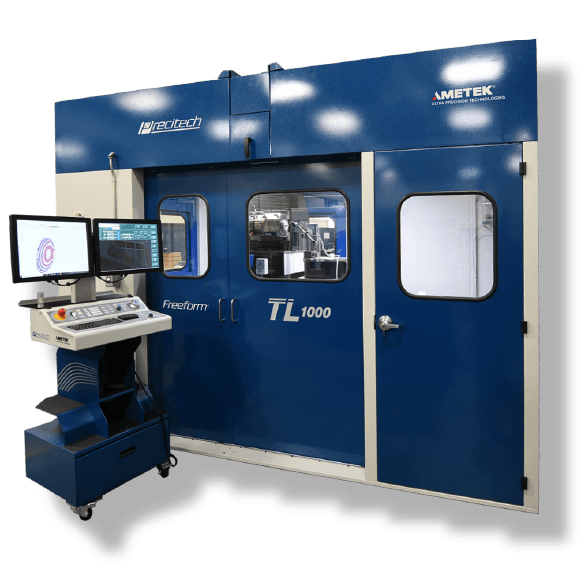

Machine name

Precitech/AMETEK’s Freeform®TL1000

(specially customized for NTKJ)

Specifications

with pico resolution of 5+2 axis enhances NTKJ to manufacture ultra-precision optics

1000 mm dia. maximum

Used for

Aspherical / free-form optics and ultra-precise products

More info about Precitech

/AMETEK’s Freeform®TL1000 here