NEWS

- February 11, 2026

-

Join NTKJ at OPIE’26 in Yokohama, Japan

NTKJ Co., Ltd. is pleased to announce our attendance for OPIE 2026 in Yokohama, Japan from 22th – 24th April, 2026. ———... Continue reading

- December 18, 2025

-

Join NTKJ at Photonics West 2026. Our booth is No.3393

NTKJ is pleased to announce our attendance to Photonics West 2026 in San Francisco on January 20th – January 22nd,... Continue reading

FEATURE

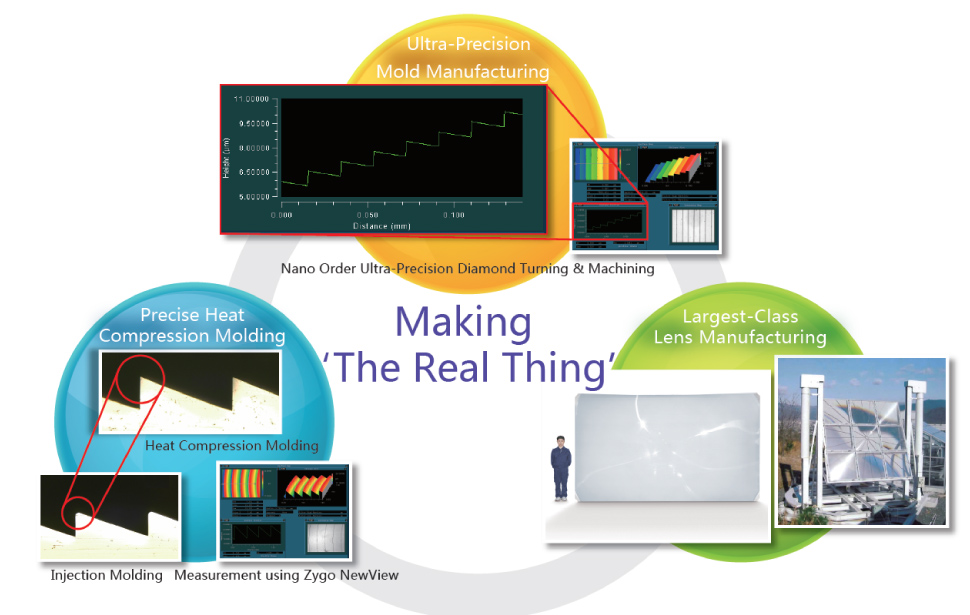

NTKJ Co., Ltd. creates high-quality,

high-precision lightweight plastic lenses featuring a thin

and efficient structure.

NTKJ Co., Ltd. creates high-quality,

high-precision lightweight plastic lenses

featuring a thin and efficient structure.

We produce plastic optical products of

practically any size, including Fresnel lens, lenticular lens, sheet prism, linear Fresnel lens, fly’s-eye lens (Micro Lens Array – MLA)and aspheric lenses. We also

produce diffraction grating, optical roll molds, free-form surface lenses and elliptical lenses, spheric

and aspheric lenses, UV and IR lenses, and light-guide plates.

NTKJ has the manufacturing expertise

and equipment to accommodate a broad range of customer needs, from prototype development to mass

production.

We pride ourselves on our high accuracy

production line, beginning from optical design and mold creation, to finished products and coating. NTKJ’s

engineers are ready and able to help you find or create the ideal product.

Our facilities can

accommodate a variety of materials and thicknesses. For prototype production or mass production of sheet

molding, do not hesitate to consult with our team.

We are ready and eager to manufacture lenses of

any type to conform to your individual specifications.

Ultra-Precision Mold Manufacturing for lenses

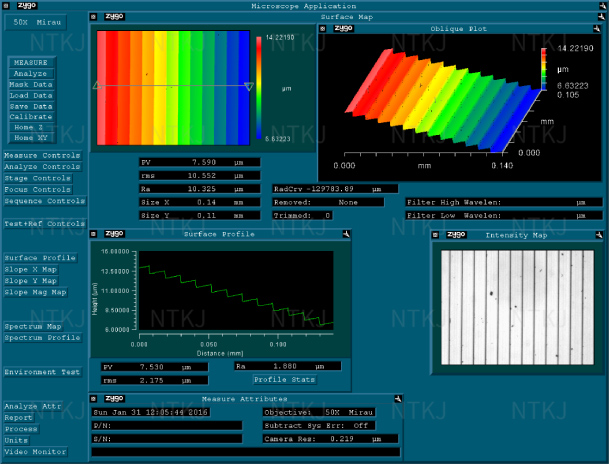

NTKJ boasts world-class level ultra-precise mold

manufacturing. Using our nano order single point diamond turning (SPDT) and machining, we are capable of

creating products with a resolution as low as 0.01 nanometer.

This extremely precise mold

manufacturing enables our lenses to be used for a variety of applications and in a variety of fields,

including:

Optics

Lighting

Medical applications

Sensing and

imaging, including remote sensing

Defense

Aerospace and Astronomy

Automotive (headlights,

LiDAR)

Augmented reality (AR) and virtual reality (VR), HMD and HUD

μTAS (Micro-total analysis

systems)

Optical communication

Infra-red (IR) lenses made of HDPE (high density polyethylene),

near-IR transmitting PMMA

Ultra-violet (UV), including UVB and UVC, made of fluoropolymer or UV

transmitting PMMA

Large aperture Germanium lenses to reduce thickness and weight

Diffractive optic

elements (DOE) and diffraction grating

Multispectral and hyperspectral imaging

We welcome requests

for custom molds.

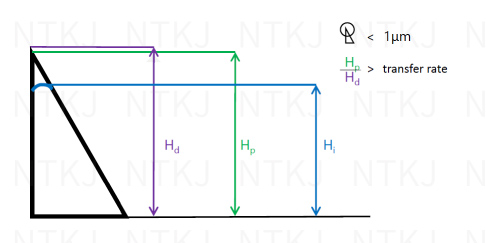

DOE measurements taken with Zygo NewView

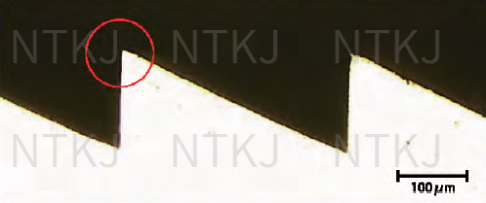

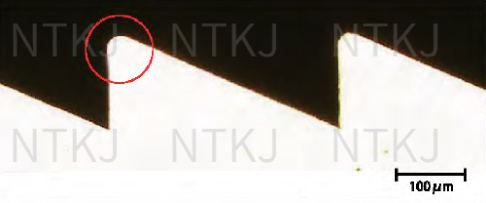

Precise Heat Compression Molding

Comparison of lens made via NTKJ's heat

compression

molding (top) vs. conventional injection molding (bottom)

NTKJ's mold pattern transfer rate

NTKJ’s high precision molding technology is used to

transfer fine optical patterns to various plastic materials, such as PMMA or PC.

Compared with

conventional injection molding, our precise heat compression molding can create lenses that are larger,

thinner, and have more precise detail. Specifically, the radius of our lens peaks can be configured to

be as low as 1 micron in size.

We are able to obtain a mold-to-lens pattern transfer rate nearing

100%. As the sketch on the left describes, we are able to nearly precisely replicate the designed height

(Hd) of the lens peaks through heat-compression (Hp), standing in contrast to the rounded lens peaks

created by injection molding (Hi).

Our precise heat-compression minimizes the amount of light

lost as it passes through the lens. For the best possible results, our heat compression molding is the

clear choice.

Largest-Class Lens Manufacturing

Our large size lenses retain the same level

of quality and precision that can be expected from standard-sized lenses. We produce massive lenses that

are unrivaled in quality and size.

For lenses larger than about 1600x1200mm, the direct cut method

is used to create super-large lenses. The direct cut method lens grooves being directly cut into the

lens material. The direct cut method, besides being used for super-large lenses, is also ideal for

one-off custom lenses or prototyping.

Maximum lens pattern machining size (direct cut): Φ5000

(roughly 4600x2700mm)

Maximum size for heat-compression: roughly 1600x1200mm

Maximum size for UV

molding: width of 1400mm

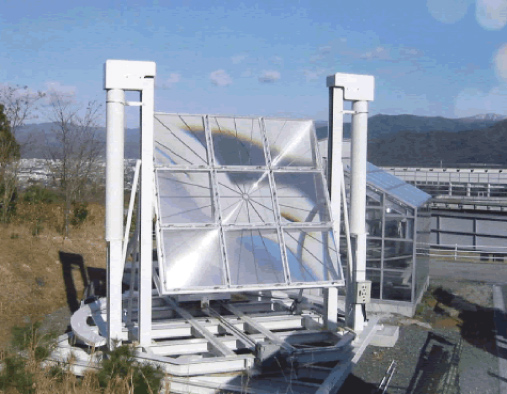

The Wakasa Wan Energy Research Center

Making ‘the real thing’ since 1974.

Nihon Tokushu Kogaku Jushi Co., Ltd. started

business in 1974 as a corporate entity manufacturing and selling high-quality, high-precision plastic

lenses. Today, we are known around Japan and internationally as a top producer of lenses. NTKJ’s

headquarters are based in Itabashi, Tokyo, known as the optics capital of Japan.

Relying on

technological expertise and manufacturing know-how gained through decades of experience, we spare no effort

in the discovery and application of ingenious ideas when developing and creating microscopic machined items.

The satisfaction of our many customers magnifies our confidence in providing

ideal solutions to your most demanding problems.

Our uniquely designed lens machining equipment can

craft lenses to microscopic tolerances, satisfying diverse requests and stringent specifications. We also

manufacture customized machining equipment for mass production. The facilities at our factory are constantly

being updated and expanded to include the most cutting-edge technology.

We firmly believe that our

distinctive capacity to produce a wide range of high-quality plastic lenses in various sizes in a timely

manner will contribute to further research and development, and to the successful commercialization of your

products. Please contact our experienced and knowledgeable staff for a consultation or

quotation.

PRODUCTS

Recently, flat prisms with finely ruled light

guide panels are widely used in LCD backlight panels, and Fresnel lenses are increasingly employed for

magnification or collector lens applications. Customized waveguides are also used for AR/VR/MR

applications.

Large-scale transmission and reflective screens, with dimensions up to 200 inches, depend

on our sophisticated Fresnel or lenticular lenses for their superior performance.

CUSTOM

About our made-to-order custom plastic lens products

About our made-to-order

custom plastic lens products

NTKJ Co., Ltd. manufactures and sells custom-made

plastic lens products. Our machining systems are ready to produce plastic optical products of practically any

size, including Fresnel, lenticular, linear Fresnel, fly’s-eye and aspheric lenses and flat prisms. Our

manufacturing expertise and equipment can accommodate a broad range of customer needs, from prototype

development to mass production.

Our uniquely designed lens machining equipment can craft lenses to

microscopic tolerances, satisfying diverse requests and stringent specifications. We also manufacture

customized machining equipment for mass production.

We firmly believe that our distinctive capacity to

produce a wide range of high-quality plastic lenses in various sizes in a timely manner will contribute to

further research and development, and to the successful commercialization of your products.

PMMA is

used for making lenses mainly. Polycarbonate can also be used. Please contact us for more detail.

Contact us to discuss the possibility of your ideal custom

product.

Examples of our made-to-order products

Examples of our

made-to-order products

Examples of our made-to-order products

Large

Fresnel lenses

Small Fresnel Lenses

Large Linear Fresnel Lenses

Small Linear Fresnel Lenses

Aspheric

Lenses

Fly’s-eye lenses / Lens array

Light Guiding Plates

Prism sheets

Projection Screens

Other

MTO Products